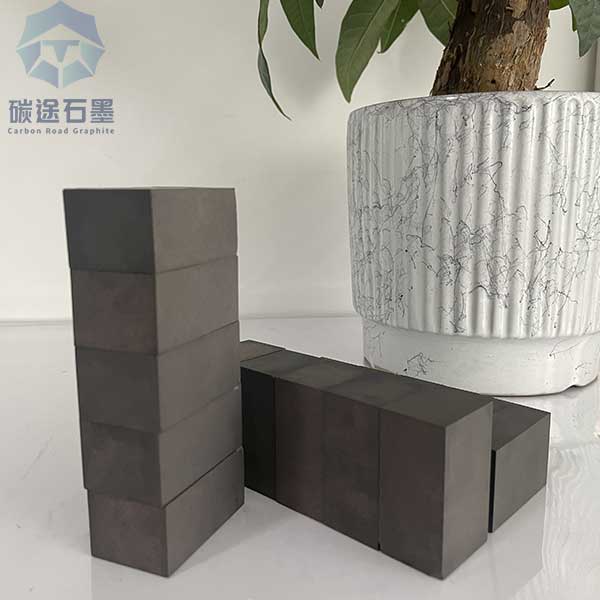

Core advantages and applications of graphite blocks in metal casting

Graphite blocks have become a key material in the modern metal casting industry due to their high thermal stability, corrosion resistance and excellent electrical conductivity. This product is designed for high-precision casting processes and is suitable for the smelting and molding of non-ferrous alloys such as aluminum, copper and zinc, significantly improving production efficiency and finished product quality.

Product features

High-purity graphite (≥99.9% C): Reduce impurity contamination and ensure the purity of molten metal.

Ultra-high temperature tolerance (≥3000°C): Maintain structural stability under continuous high temperature environment and extend mold life.

Low thermal expansion coefficient: Reduce casting deformation and improve dimensional accuracy (tolerance ±0.5mm).

Excellent thermal conductivity: Accelerate melt cooling and shorten production cycle.

Application scenarios

Die casting molds: used for complex structural parts such as automotive parts and electronic housings.

Crucible and furnace lining: Acid and alkali resistant, suitable for precious metal smelting.

Continuous casting: As a crystallizer material, improve surface finish (Ra≤1.6μm).

Technical parameters

Size: standard 500×300×200mm, customized is supported.

Density: 1.75–1.85 g/cm³.

Resistivity: ≤12 μΩ·m (25°C).

Choose our graphite blocks to provide efficient, environmentally friendly and low-cost solutions for your casting process!